Services

Repair mechanical seals

If you entrust your mechanical seals to us, they will be processed as follows:

- Intake: receipt of your mechanical seal and entry in register of serial numbers

- Visual check: enlargement

- Ultrasonic cleaning

- Sand-blasting if necessary

- Pre-treatment in the case of run-in grooves

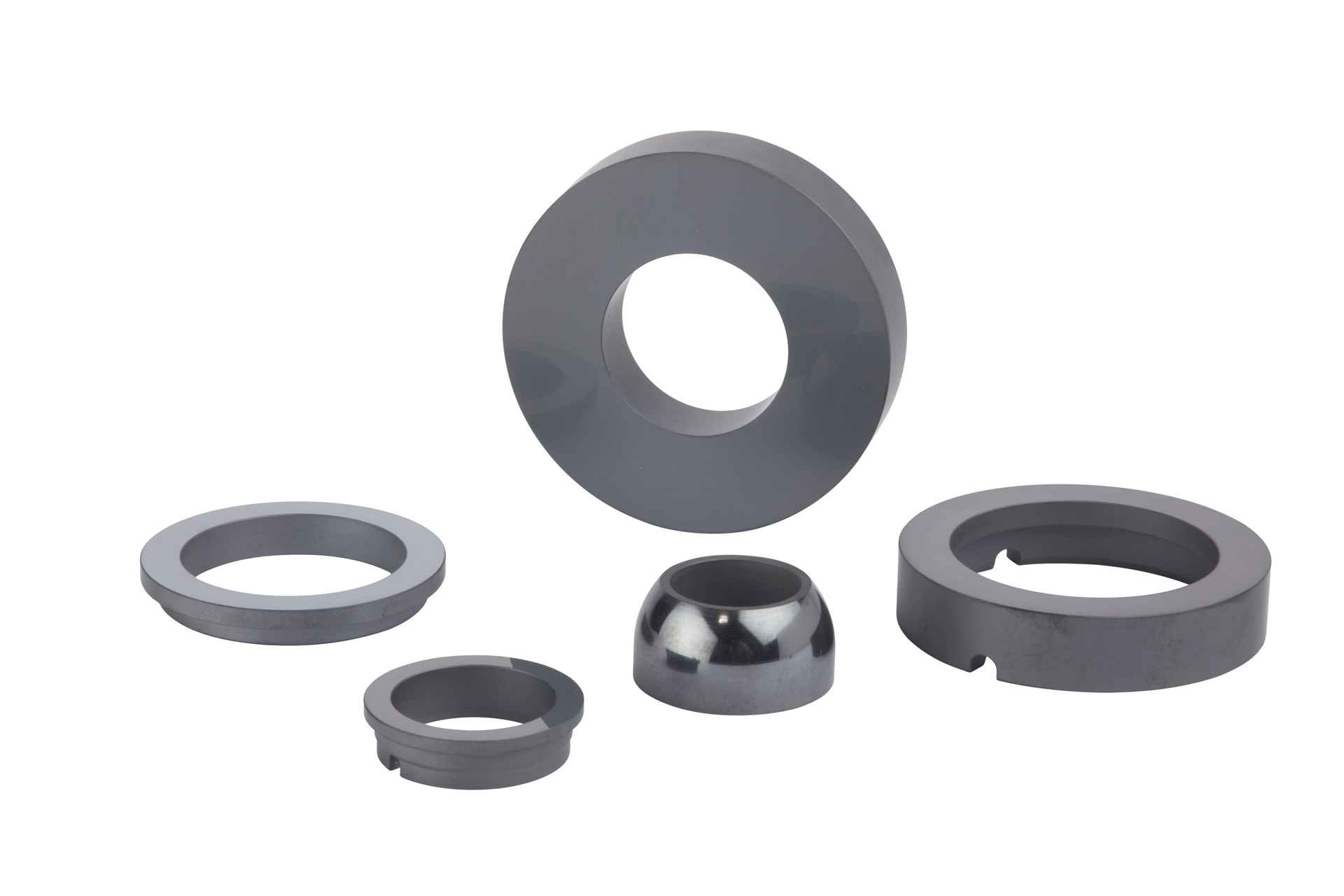

- Preparatory and finish lapping: 25 – 6 and 2 µ of the sliding surface on production machines for all materials:

- silicon carbide, tungsten carbide, stainless steel, carbon. Any corrections in deliberation with customer.

- Cleaning sliding surfaces after lapping

- Check by means of monochromatic light and flat glass

- Fitting the seal and replacing O-rings

- Final check: pressure test by cartridge seals

- Dispatch: archiving the work sheet